Description

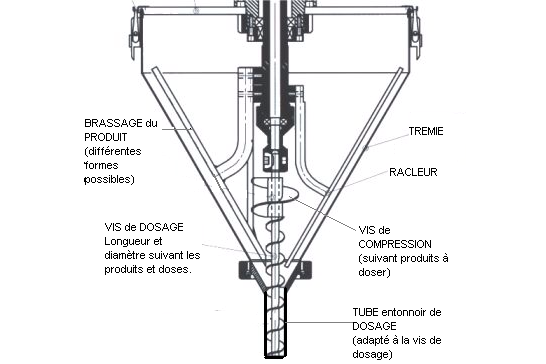

At the end of the drive shaft, a dosing screw is fixed inside the hopper.

This screw consists of two parts:

-

A compression screw, located at the top of the dosing screw, pushes the product into the screw flights. This compression screw may have flights with a variable diameter (as shown in the diagram below) or flights with a constant diameter. The choice depends on the product characteristics (density, viscosity, particle size, fragility, etc.).

-

A dosing screw, with constant-diameter flights. This screw guides the product through the tube and, thanks to its regular pitch, doses the product. A dosing screw is defined by two parameters: the diameter and the pitch between the flights. The screw selection depends on the product's characteristics and the required output rate. The larger the diameter, the higher the dose, and therefore, the faster the dosing process.

The funnel tube generally has a diameter matching the screw (in practice, the same diameter plus a few millimeters of clearance). At the end of this tube, various accessories can be attached to slow down the product flow or slightly compact the product to facilitate filling.

This tube is easily removable (fixed by a slotted nut, removable without tools).

With each rotation of the screw, one dose is dispensed into the bag or container. By knowing the pitch, diameter, number of turns, and time, it is possible to dose a precise volume.

When the doser is installed above a vertical form-fill-seal machine, dosing is usually volumetric.

If the line includes a weighing control system, the doser can automatically adjust the volume discharged by the screw.

When the doser is mounted on a stand and used to fill preformed pouches or boxes, the operation can be controlled using a weighing scale. The container is weighed (this is the tare), then the doser starts and fills until the desired weight is reached.

When products are fragile or have particle sizes too large for a screw, dosing can be done using the system shown below, called the SPINNER PLATE and COWL.

The product descends into the funnel tube and rests on a small rotating plate. The space between the edge of the plate and the funnel defines the volume. With each rotation, a volume is projected above the plate into the product guide cone.

This dosing tool allows for dosing products such as: chickpeas, soups with croutons, rice, coarse semolina, but also instant coffee, which is very fragile and gets damaged by a dosing screw.

.png)