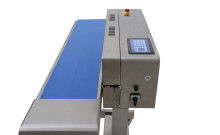

All In Sealer D542 AHSV

Validatable continuous stainless-steel sealer for closing bags in medical and pharmaceutical environments. Built-in conveyor; bags are placed horizontally.

En savoir plusDescription

The All In Sealer D542 AHSV vertical continuous sealer is suitable for sealing all types of sterile pouches, barrier bags, and all kinds of plastic, composite, or kraft bags with validation.

The unit is constructed entirely from high-quality stainless steel (frame and sealing head) to ensure durability, easy cleaning, and hygiene suitable for the medical sector.

This medical-grade model allows validation of all critical sealing parameters — temperature, sealing time, and sealing pressure — in compliance with ISO 11607-2 and the EN 868-5, EN 868-9, EN-ISO 12100, and EN-ISO 13850 standards for use in medical and pharmaceutical environments. An alarm is triggered if any of the sealing parameters deviate from the set values.

Franco Pack offers comprehensive calibration and validation services, providing a calibration certificate as well as IQ/OQ qualification documentation.

The entire unit is mounted on four castors, two of which have brakes, making the machine highly mobile. The sealing head and conveyor can be tilted up to 30° to facilitate work with bulk product bags. A small platform at the conveyor entry assists with positioning the bag before feeding it into the machine, while an adjustable depth guide ensures accurate alignment of the bag’s top edge with the sealing area.

Once the bag top is introduced between the transport belts, the sealing area passes continuously between PTFE (Teflon) belts, through heating bars and then cooling bars. Finally, before releasing the bag, pressure rollers ensure a perfect seal.

The control interface is a touchscreen display from which you can adjust all critical sealing parameters — speed, temperature, and sealing pressure — as well as the height of the sealing head and the conveyor height relative to the sealing head. This provides excellent flexibility for sealing large or gusseted bags. Up to 50 different programs can be stored.

To ensure security, there are three access levels for parameter settings: operators, supervisors, and administrators. It is also possible to record batch and cycle data via USB port.

All All In Sealer D542 models are equipped with an automatic cooling mode. If the machine is stopped while the sealing temperature is above 80°C, it will automatically cool down until the temperature drops below 80°C, then switch to standby mode. These functions help preserve the PTFE belts during shutdown procedures.

A range of accessories and optional features are available to optimize your configuration according to your specific needs.

- Reference

- D542 AHSV

- Sealing width

- 10 mm

20 mm (optional) - Maximum film thickness

- 2 x 200 microns

- Minimum film thickness

- 2 x 20 microns

- Coating

- Stainless steel

- Sealing type

- Heat sealing

- Max. height bags / sealing

- 40 mm

- Validation

- Yes

- Max. saeling speed

- 10 m/min

- Conveyor direction

- Left-Right (optional)

Right-Left - Conveyor width

- 250 mm

- Protection IP

- IP 20

- Voltage

- 230 V mono

- Consumption

- 1100 W

- Maximum Product Weight

- 10 kg

- Conveyor speed

- 10 meter per minute

- Net weight

- 110 kg

- Dimensions machine

- 1400 x 590 x 1010 mm (with conveyor)

- Regulatory Framework

- 2006/42/CE; 2014/30/UE

- General Safety

- EN-ISO 12100; EN-ISO 14118; EN-IEC 60204+1; EN-ISO 13850

- Sterilization and Packaging

- ISO 11607-1; EN 868-5; EN 868-9

- Temperature measurement and monitoring

- EN-ISO 13732-1