All In Sealer D 542 AVTSV

Validatable continuous stainless-steel sealer for closing bags in medical and pharmaceutical environments. Features an integrated conveyor for vertical bag placement. Can also be supplied without a conveyor for integration into existing production lines.

En savoir plusDescription

The All In Sealer D542 AVTSV vertical continuous sealer is designed for sealing all types of sterile pouches, barrier bags, as well as any kind of plastic, complex, or kraft paper bags, with full validation capability.

The unit is built entirely from high-quality stainless steel (frame and sealing head) to ensure durability, easy cleaning, and hygiene standards suitable for the medical sector.

This medical-grade model allows validation of all critical sealing parameters — temperature, sealing time, and sealing pressure — and complies with ISO 11607-2, as well as EN 868-5, EN 868-9, EN-ISO 12100, and EN-ISO 13850 standards for use in medical and pharmaceutical environments. If any sealing parameter falls outside the set limits, an alarm will automatically be triggered.

Franco Pack provides full calibration and validation services, including the issuance of calibration certificates and IQ/OQ qualification documentation.

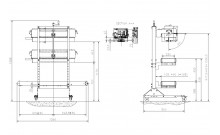

The sealing head and conveyor assembly are mounted on four casters, two of which are lockable, making the machine highly mobile. The conveyor height can be adjusted in 75 mm increments for easy connection with other conveyors upstream or downstream. A guide rail on the conveyor head assists with smooth bag insertion. To accommodate different bag lengths, the sealing head height can be adjusted using a hand crank.

Once inserted, bags pass through the sealing zone, moving continuously between Teflon bands, through heating bars and then cooling bars. Before the bag is released, pressure rollers ensure a perfect seal.

The touchscreen control interface allows easy adjustment of all critical sealing parameters (speed, temperature, and pressure), as well as the sealing head height — providing great flexibility for bulky or gusseted pouches. Up to 50 different programs can be stored.

To ensure process security, there are three levels of access: operator, supervisor, and administrator. Batch and cycle data can be recorded via USB port.

The machine can also be supplied without a conveyor, for integration into existing production lines already equipped with a bag-support conveyor. In this case, it is important to verify speed synchronization compatibility.

All All In Sealer D542 units are equipped with an automatic cooling mode. If the machine is stopped while the sealing temperature exceeds 80°C, it will automatically cool down until the temperature drops below 80°C, then switch to standby mode. This feature helps protect the Teflon bands during shutdown procedures.

Additional accessories and options are available to optimize the configuration for your specific requirements.

- Reference

- D 542 AVTSV

- Sealing width

- 10 mm

20 mm (optional) - Maximum film thickness

- 2 x 200 microns

- Minimum film thickness

- 2 x 20 microns

- Coating

- Stainless steel

- Sealing type

- Heat sealing

- Max. height bags / sealing

- 40 mm

- Validation

- Yes

- Max. saeling speed

- 10 m/min

- Conveyor direction

- Left-Right (optional)

Right-Left - Conveyor width

- 250 mm

- Protection IP

- IP 20

- Voltage

- 230 V mono

- Consumption

- 1100 W

- Maximum Product Weight

- 10 kg

- Net weight

- 110 kg

- Dimensions machine

- 1450 x 810 x 800 mm à 1630 mm (with conveyor)

- Regulatory Framework

- 2006/42/CE; 2014/30/UE; 2011/65/UE+2015/863

- General Safety

- EN-ISO 12100:2010; EN-ISO 13850:2015; EN-ISO 14118:2018; EN-IEC 60204-1:2018; ISO/TS 16775:2021

- Sterilization and Packaging

- EN-ISO 11607-2:2020; EN 868-5:2018

- Temperature measurement and monitoring

- ISO/TS 16775:2021; EN 868-5:2018; DIN 58953-7:2020